The aim of this article is to analyse the machining parameters calculation for basic milling operations. In case that you have not read our previous article that explains the basics on machining parameters and discusses their selection, it will be better to read it now by clicking this link as the present article is based on that.

Nevertheless, the simplified 2D approach to machining processes, which was discussed last time, is to be reminded. Based on the basic chip formation mechanism, the main machining parameters are the Cutting Speed (VC) and the initial chip thickness (t0) and these define the programmed speed of the spindle (RPM) and feedrate of the cutting tool (mm/min).

Next, the basic 2D chip formation model will be connected with the basic geometry of the cutting region during milling so as to better understand the programming of the relevant speeds and feeds.

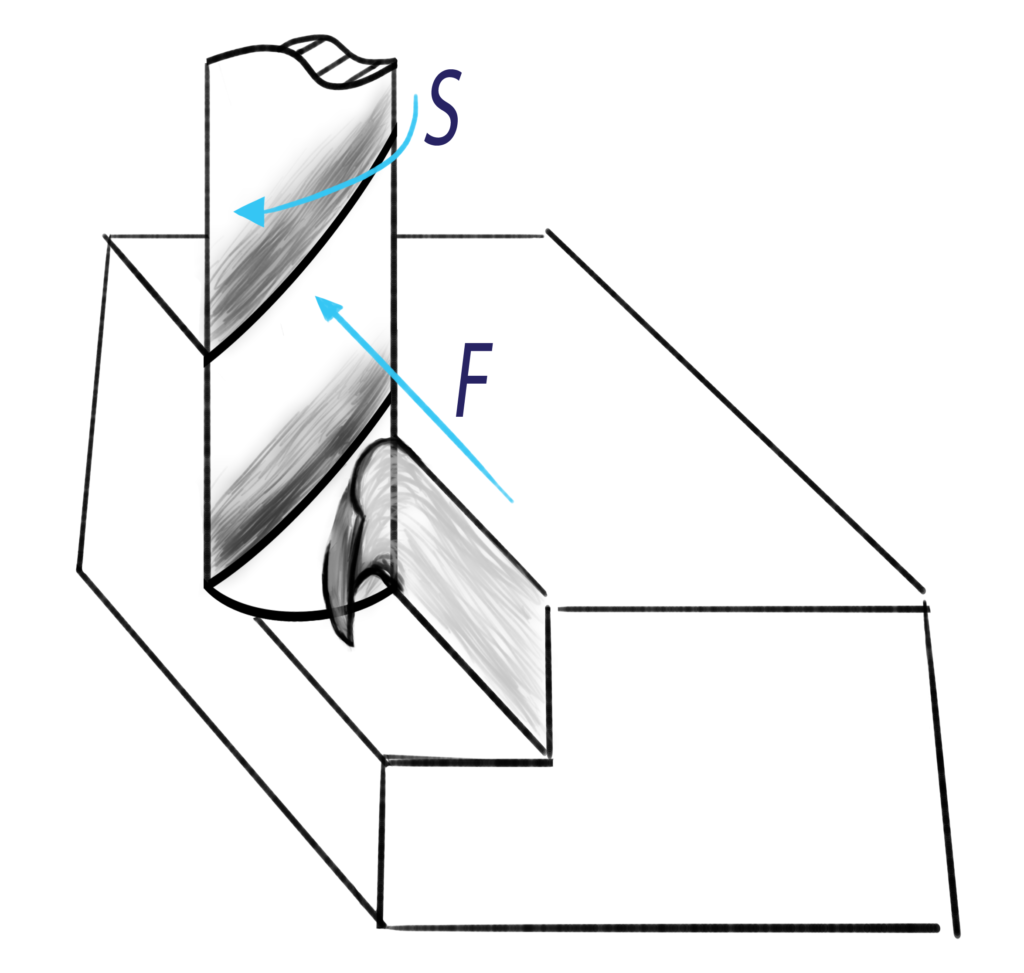

Overviewing milling process, it can be said that chip formation occurs because of the cutting edges of the rotating cutting tool collide with the stationary part which is attached to a work holding device. This implies that the cutting speed that is required to initiate the chip formation process is the result of the relative speed of the rotating cutting tool edges against the rotating part. Understanding this relative motion and observing the milling procedure from the right perspective, we can conclude that the chip formation process during milling directly reflects to the basic model that has been already analysed. Thus, it can be realized that the cutting speed of the basic chip formation model is directly related to the rotational speed of the spindle and thus the linear speed of the cutting tool edges due to their rotation around the axis of the spindle.

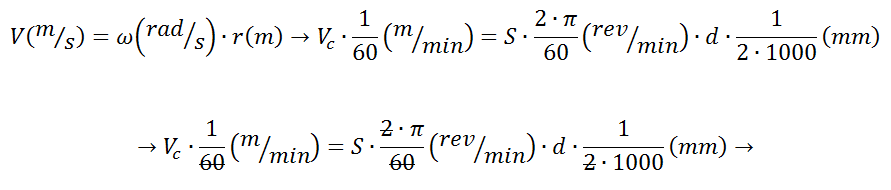

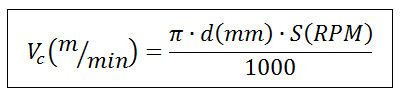

Based on the previous assumptions and realisations, we can define the relation between the rotational speed of the cutting tool and the cutting speed that each individual edge is to face. This is to define the formula that connects the cutting speed of the milling process when the cutting tool with specified diameter removes material rotating around its axis at a programmed rotational speed (RPM). Thus, if we start our analysis by defining the formula that governs the simple rotational motion and transform it so as to use more machinist friendly units, we get the following:

Where

S: the programmed rotational speed of the machine tool spindle in RPM

VC: the cutting speed in m⁄min, as it is suggested by the relevant combination of cutting tool the workpiece material and any other parameter has been already discussed here.

d: the diameter of the cutting tool in mm

or if we solve the formula so as to get the rotational speed of the spindle:

The two last formulas are of great importance as we have to recalculate the spindle rotational speed every time we change the cutting tool or the machined material.

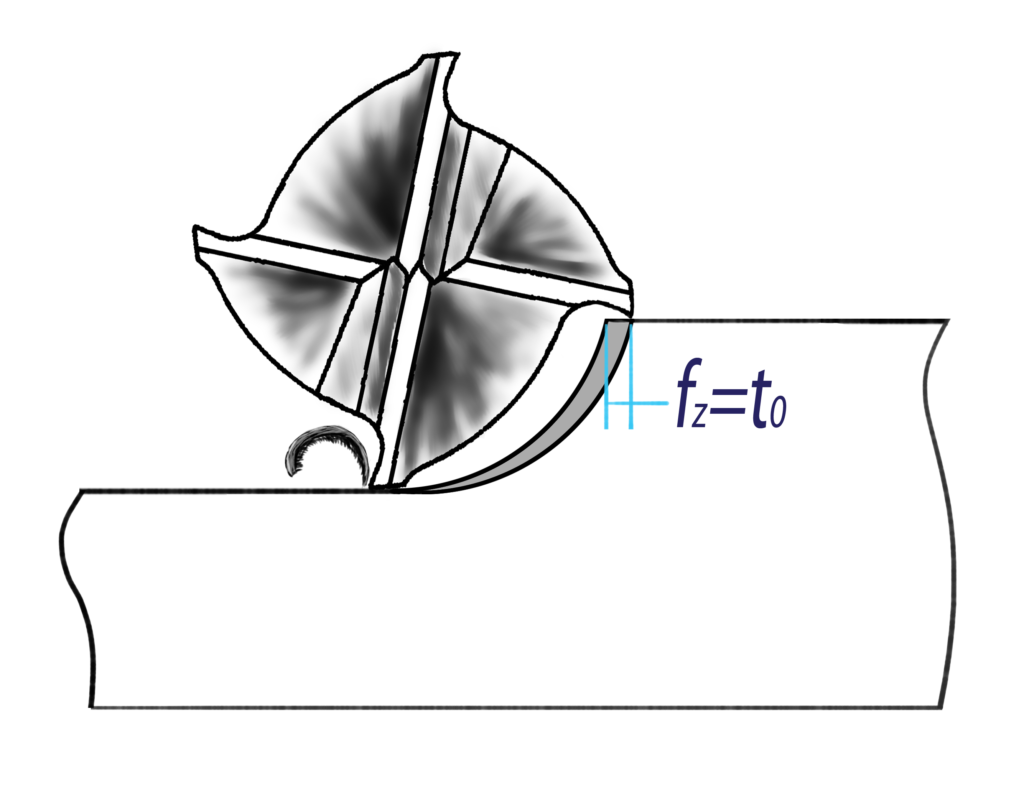

The second parameter that has to be programmed so as to make the milling possible is the tool feedrate (F). Feedrate, which is programmed in mm/min for milling operations, refers to the linear velocity of the cutting tool axis relatively to the surface of the stationary workpiece. Observing the geometry of the region that the actual chip removal occurs, we can state that a chip, with an initial thickness of , is getting removed due to the relative motion of the rotating tool’s cutting edge against the workpiece. This initial thickness of the chip is directly related with the initial chip thickness of the basic chip formation model and is equal to the distance that the tool feeds forward between the moments of the engagement of two sequential cutting edges of the tool with the workpiece. This is why it is called “feed per tooth” of the cutting tool.

The feed per tooth of the cutting tool falls into the restrictions about the initial chip thickness that were discussed on our previous article and the programmer have to make sure that the actual feed per tooth values are within the acceptable limits.

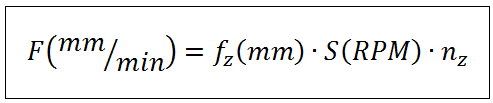

The calculation of the programmed feedrate of the cutting tool in mm/min is being done by using the following formula that shows that the actual feedrate is equal to the feed per tooth times the rotational speed of the spindle and the number of teeth of the cutting tool.

Where

F: the programmable feedrate in mm/min

fz: the feed per tooth of the cutting tool in mm

S: the programmed rotational speed of the machine tool spindle in RPM

nz: the number of teeth / cutting edges of the cutting tool

The optimal selection of the cutting tool depends on the milling process that we have to undertake and our productivity or accuracy expectations. When we select a cutting tool, the manufacturer always provides the two basic machining parameters, which are the cutting speed and the feed per tooth of the cutting tool, and we are responsible for the calculation of the best applicable feed and spindle speed by using the provided formulas.

A common speculation is the fact that the manufacturers usually provide a relatively wide value range for the cutting speed and the feed per tooth. Thus, the main problem is the selection of the best values for a specific milling process. We are going to reinvestigate this problem in upcoming articles but first we have to discuss and understand the various parameters that are involved to machining operations and how they affect the selection of the optimal machining parameters.

Finally, it has to be mentioned that there are machinists’ calculators that are capable of calculating the speeds and feeds according to the previous formulas. Also, there are numerous smartphone applications that can calculate the machining parameters according to the formulas.

My personal choice is the MechTab application that is free and available for both Android and iOS users.

If you want to stay updated and get informed for our upcoming articles, you can subscribe to our newsletter and we will keep you informed about our new articles and our activities.

Also, do not hesitate to contact us for every question or problem regarding the CNC machining and programming and we will be happy to help you find the best possible solution!